Showing 1–21 of 35 results

-

$381.43 Quick View

$381.43 Quick View“C-2” Double Chock w/Tightener, Padlock & Flag

Manufactured by Aldon®

4011-08

$381.43

-

$364.64 Quick View

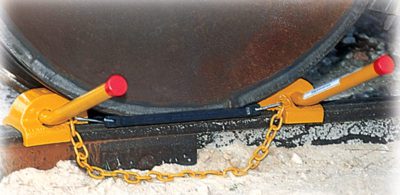

$364.64 Quick ViewRail Clamping Wheel Block CB6-B (105-142 lbs. Rail)

Manufactured by Aldon®

4016-02

$364.64

-

$362.98 Quick View

$362.98 Quick ViewErgonomic “C” Double Chock w/Flag – Exposed Rail

Manufactured by Aldon®

4011-16

$362.98

-

$362.94 Quick View

$362.94 Quick ViewErgonomic “C-1” Double Chock w/Flag – Flush Rail

Manufactured by Aldon®

4011-17

$362.94

-

Price range: $369.15 through $378.55 Quick View

Price range: $369.15 through $378.55 Quick ViewSpark-Proof Urethane Heavy-Duty Double Wheel Chock

Manufactured by Aldon®

4011-40 & 4011-41

Price range: $369.15 through $378.55

-

$343.63 Quick View

$343.63 Quick ViewDouble Railroad Wheel Chock With Tension Clamp & Padlock

Manufactured by Aldon®

4011-05

$343.63

-

Price range: $309.88 through $317.15 Quick View

Price range: $309.88 through $317.15 Quick ViewTransit Car Urethane Double Chock

Manufactured by Aldon®

4011-12 & 4011-13

Price range: $309.88 through $317.15

-

$281.30 Quick View

$281.30 Quick ViewRail Clamping Wheel Block CB6-A (60-104 lbs. Rail)

Manufactured by Aldon®

4016-01

$281.30

-

$260.28 Quick View

$260.28 Quick ViewWhack ‘Em Dbl Railroad Wheel Chock w/Flag – Exposed Rail

Manufactured by Aldon®

4011-34

$260.28

-

$260.28 Quick View

$260.28 Quick ViewWhack ‘Em Dbl Railroad Wheel Chock w/Flag – Flush Rail

Manufactured by Aldon®

4011-35

$260.28

-

Price range: $262.50 through $270.51 Quick View

Price range: $262.50 through $270.51 Quick ViewSpark-Proof Urethane Double Wheel Chock for 12″-24″ Wheels

Manufactured by Aldon®

4011-44 & 4011-45

Price range: $262.50 through $270.51

-

$250.75 Quick View

$250.75 Quick ViewDouble Railroad Wheel Chock with Flag (Flush Rail)

Manufactured by Aldon®

4011-07

$250.75

-

$250.50 Quick View

$250.50 Quick ViewDouble Railroad Wheel Chock with Flag (Exposed Rail)

Manufactured by Aldon®

4011-06

$250.50

-

$212.63 Quick View

$212.63 Quick ViewSpark-Proof Urethane Heavy-Duty Single Wheel Chock (Flush Rail)

Manufactured by Aldon®

4011-43

$212.63

-

$210.40 Quick View

$210.40 Quick ViewWhack ‘Em Double Railroad Wheel Chock – Exposed Rail

Manufactured by Aldon®

4011-30

$210.40

-

$210.40 Quick View

$210.40 Quick ViewWhack ‘Em Double Railroad Wheel Chock – Flush Rail

Manufactured by Aldon®

4011-31

$210.40

-

$206.69 Quick View

$206.69 Quick ViewErgonomic “A” Single Chock w/Flag – Exposed Rail

Manufactured by Aldon®

4011-14

$206.69

-

$206.69 Quick View

$206.69 Quick ViewErgonomic “A-1” Single Chock w/Flag – Flush Rail

Manufactured by Aldon®

4011-15

$206.69

-

$205.33 Quick View

$205.33 Quick ViewSpark-Proof Urethane Heavy-Duty Single Wheel Chock (Exposed Rail)

Manufactured by Aldon®

4011-42

$205.33

-

$202.26 Quick View

$202.26 Quick ViewDouble Railroad Wheel Chock (Exposed Rail)

Manufactured by Aldon®

4011-03

$202.26

-

$202.26 Quick View

$202.26 Quick ViewDouble Railroad Wheel Chock (Flush Rail)

Manufactured by Aldon®

4011-04

$202.26

Frequently Asked Questions

Why use rail chocks?

A gust of wind is enough to cause a 285,000-pound freight car to start rolling. Thanks, in part to roller bearings, freight car wheels offer very little resistance to movement. This is why moving heavy loads by rail is so efficient. But at the same time, all this mass, so easily moved, needs to be securely blocked while the car is being worked.

Aldon® rail chocks have the edge! Our all-steel construction wheel chocks have replaceable rail biting spurs for securing locomotives and freight cars on exposed or flush rail. The spur is the key to effective chocking and superior gripping power.

Why use urethane wheel chocks?

For those needing a spark-proof chock when loading or unloading tank cars and freight cars, where a spark from a steel wheel chock could ignite dust or fumes, urethane wheel chocks are the answer. Urethane combines excellent resistance to loads with the ability to compress to half its thickness and then spring back to its original shape. Resilient enough for a locomotive to pull the car over the chock without derailing.

Should wheel chocks be used with car brakes?

Wheel chocks should be used in addition to car brakes whenever railcars are being worked. One type of chock, however, does not fit every situation. Contact our on-site sales engineers to guide you to the correct chock to use for your application.