Important Wheel Chock Information

A gust of wind is enough to cause a 260,000-pound freight car to start rolling. Thanks to roller bearings, freight car wheels offer very little resistance to movement. The contact area of each wheel on the rail is smaller that the size of a dime. This is why moving heavy loads by rail is so efficient! But at the same time, all this mass, so easily moved, needs to be securely blocked while the car is being worked.

Loading freight cars increases the strain on the car brakes. Liquid pouring into a tank car or a forklift moving back and forth in a boxcar creates dynamic forces which can overcome the holding power of the brakes.

Slack in mechanical car brakes can be enough to allow a wheel to move forward a few inches and dislodge a dock board or strain a hose line

This is why OSHA mandates the use of wheel chocks in addition to car brakes wherever rail cars are being worked.

Aldon® Chocks have the Edge

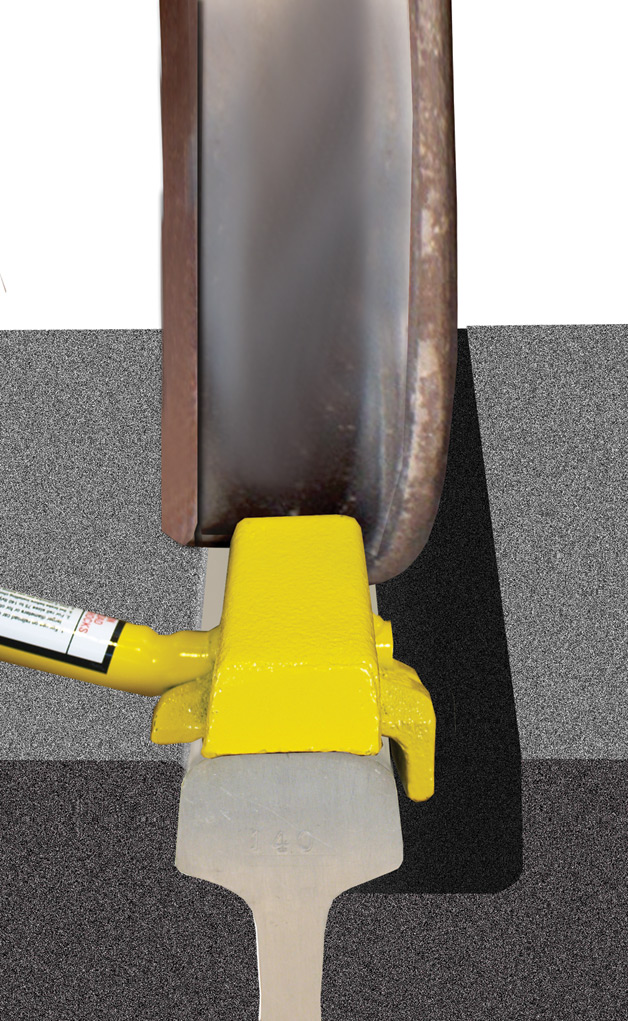

In 1955 Aldon Company, Inc. introduced cast steel chocks with the unique feature of replaceable spurs (or teeth). The spur is the key to effective choking. Under wheel pressure, the spur bites into the hard, smooth surface of the rail to keep the chock from sliding. But eventually, like the blades of a knife, the spur edge will become dull from use.

A dull spur can’t bite into the rail to keep the chock from sliding. You can keep the sure grip of an Aldon® wheel chock by turning the spur to three new sharp edges and then replacing the spurs at minimal cost instead of buying a new wheel chock.

It’s easy to turn and replace worn spurs in Aldon® Chocks

Chock spurs have four edges. When the first edge becomes dulled from use, you can tap the spur out of its slot and re-insert it with a fresh edge exposed. By turning the spurs at intervals you extend the service life and effectiveness of your wheel chocks.

Learn more about changing out chock spurs. View our Instruction Manual or watch our short video on chock spur maintenance.

What Kind of Rail Do You Have?

One type of chock does not fit every rail situation. Aldon® offers flush rail chocks and exposed rail chocks. Exposed rail is open to the ties. Flush rail is encased in the pavement, with only a flangeway left open on the inside of both rails for wheels to pass through.

Single Chocks or Double Chocks

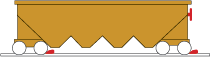

Recommended chocking procedures for single cars on a flat track

If the track is flat and there is no vibration, double chocks at each end can be used to block car movement.

Set brake before chocking.

If the car tends to roll in one direction, single chocks at each end may be sufficient.

Set brake before chocking.

Double Chocks on each end of the car provide two-chock blocking against movement in either direction.

Set brake before chocking.

Recommended chocking procedures for multiple cars on a flat track

In a line of coupled freight cars, on a flat track, brake, and chock the car to be worked. It may be necessary to apply the brake to several coupled cars depending on operating conditions or track conditions.

Repeat the braking and chocking of each subsequent car to be worked. Chock both ends of the car being worked. Always use double chocks at both ends of the car.

Car on a sloped track

Do not use wheel chocks on sloped track. Use car stops or rail skates. (NO IMPACT)