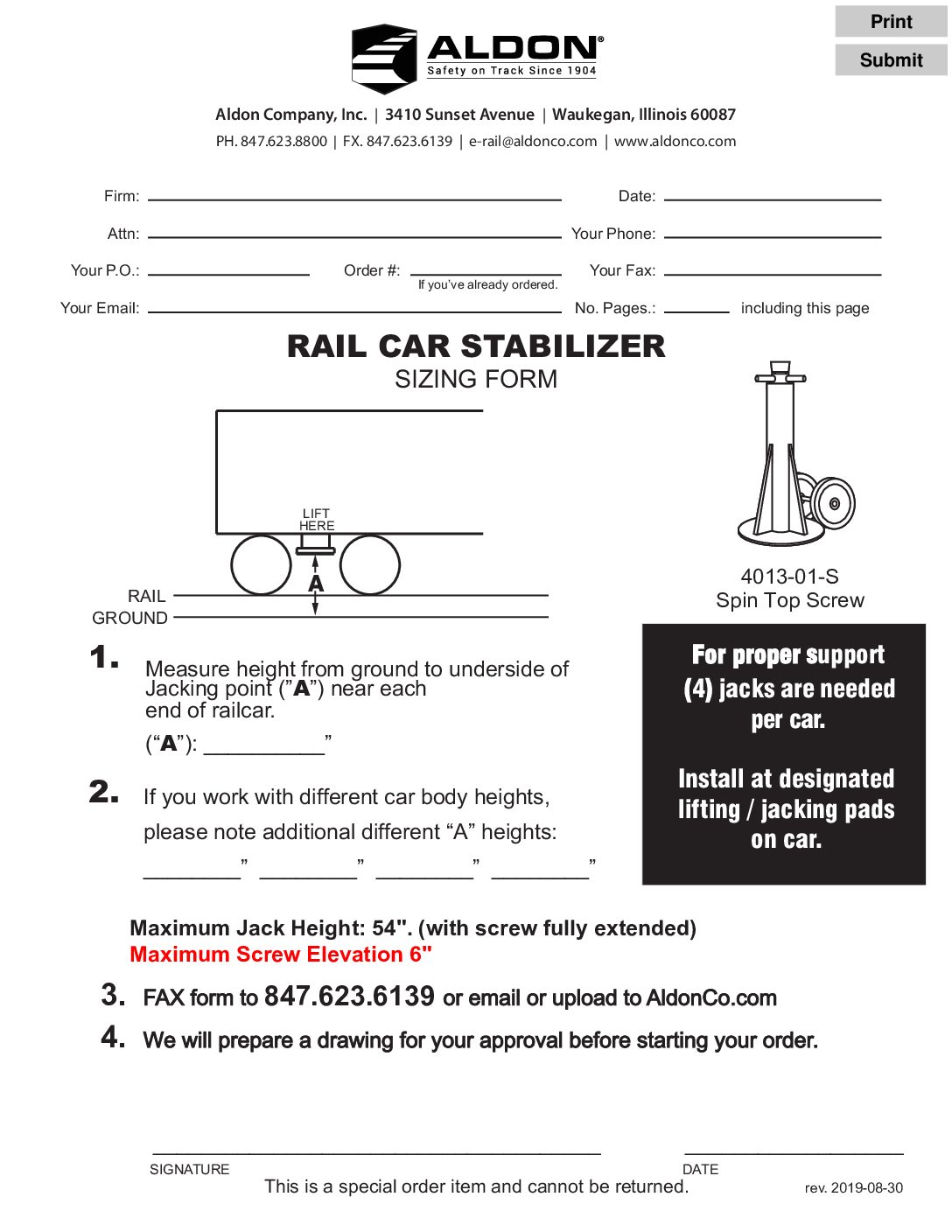

Our Sizing Form provides essential information to help us ensure that we deliver the best quality of your made-to-order item. We cannot process your order without the required information from the Sizing Form.

- You can locate the Sizing Form by scrolling to the “Product Resources” section. Click to open the “fillable” PDF document and complete the information needed to process your order. Save the file and submit the completed Sizing Form by going to the “Upload Completed Sizing Form” located within the Orange Box.

- You may need to open the form in Adobe Acrobat Reader rather than in your browser for the fillable boxes to be active.

It is ideal, but not essential, to submit your form with your order. If you are having issues with filling out the form electronically, you can print the form, fill it out, and then fax (847.623.6139), scan and email ([email protected]), or mail it (3410 Sunset Ave, Waukegan, IL 60087).